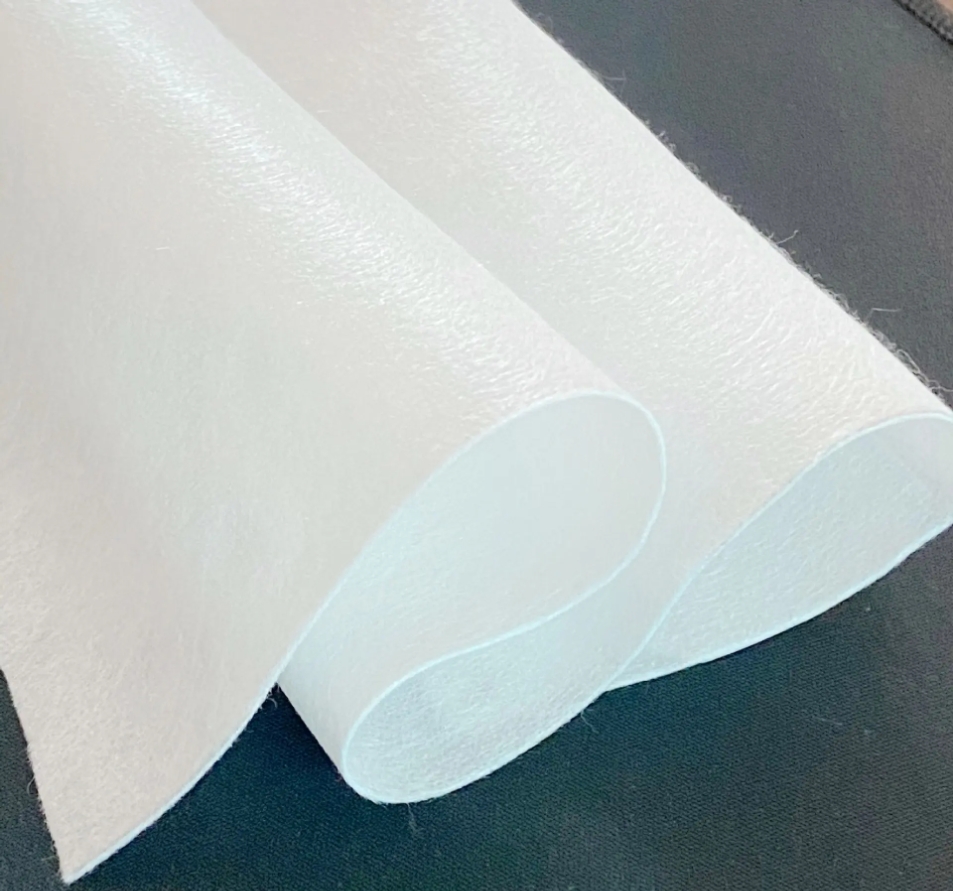

Spunlaced nonwoven fabrics: technological innovation and wide application

**introduction**

Nonwovens, also known as nonwovens, are fabrics that can be made without the traditional weaving process. Spunlace non-woven fabrics, as one of them, use spunlace technology to reinforce fiber webs into fabrics. They have unique properties and a wide range of applications.

**Introduction to Spunlace Technology**

The production process of spunlace nonwovens involves forming short fibers or filaments into a web and then strengthening the fiber web through high-pressure water flow (spunlace). Spunlace technology uses the impact of high-speed water flow to entangle and bond the fibers in the fiber web to form a non-woven fabric with certain strength and stability.

**Characteristics of spunlaced non-woven fabrics**

1. **High Strength**: The spunlace-reinforced non-woven fabric has high strength and wear resistance.

2. **Softness**: Compared with mechanically reinforced non-woven fabrics, spunlaced non-woven fabrics are softer and more skin-friendly.

3. **Breathability**: Spunlaced non-woven fabric has good breathability and is suitable for applications that require good breathability.

4. **Environmental protection**: The spunlace process does not require the use of adhesives or chemical additives and is more environmentally friendly.

5. **Versatility**: The type of fiber and the structure of the web can be adjusted according to different needs to produce non-woven fabrics with different properties.

**Application of spunlaced non-woven fabric**

1. **Medical and health field**: Spunlaced non-woven fabrics are often used to make surgical gowns, masks, medical bed sheets, etc. due to their high cleanliness and sterile properties.

2. **Personal care products**: such as sanitary napkins, diapers, etc., due to their high absorbency and softness.

3. **Household Items**: Such as tablecloths, sheets, towels, etc. for their durability and comfort.

4. **Industrial use**: such as filter materials, insulation materials, reinforcement materials, etc. due to its high strength and stability.

5. **Agricultural field**: Such as covering materials, plant growth substrates, etc., due to their breathability and moisture retention.

**production process**

The production of spunlace non-woven fabrics mainly includes the following steps:

1. **Fiber preparation**: Choose appropriate fiber materials, such as polyester, viscose, cotton, etc.

2. **Net forming**: Laying the fibers into a uniform network structure through air flow or mechanical means.

3. **Spunlace reinforcement**: Through spunlace equipment, high-pressure water flow is used to reinforce the fiber web.

4. **Drying**: Dry the reinforced non-woven fabric to ensure its stability.

5. **Post-processing**: Carry out post-processing processes such as dyeing, coating, and cutting as needed.

**Conclusion**

With its unique production technology and excellent product performance, spunlace nonwoven fabrics have shown wide application potential in many fields. With the continuous advancement and innovation of technology, spunlace non-woven fabrics are expected to play a greater role in the future and meet the needs of more industries.

**Call to Action**

Learn more about spunlace nonwovens, explore their application possibilities in your industry, and let’s promote the use of sustainable and environmentally friendly materials together.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

LA

LA